Removing Sheet Metal Friction Nuts On Base Of Lamp

Also need to make sure metal base strong enough to hold weight of lamp straight.

Removing sheet metal friction nuts on base of lamp. The metal base is 5 deep. Use a drill bit or holecutter to make the 1 25mm lamp hole s required. Use firm pressure and be careful to keep the vinegar off the lampshade when possible. This should only be done if the conductor is not close to a highly charged object or a to metal sheet that is at high voltage.

Remove the cover of the device and attach the base to the gasket and duct using included sheet metal screws. Must be the lye in concrete. Still thinking through what to use to make it heavier. On a continued note the concrete inner base covered in hard plastic coating just disintegrated plastic also.

Use alcohol to remove any dirt and or fingerprints from the lamp. Over time metal objects are subject to rust and corrosion. Removing or avoiding charge on materials. If the rust persists add a small amount of baking soda to the rag and use this to scrub.

Most lamp sockets attach to a lamp base by using a mounting nut attached to a bracket located on the bottom of the socket. It can become a major complication if you re removing or replacing an object that is secured by the. About 150 different lamp kits lamp sockets cord sets finials lamp harps lamp hardware switches plugs nickel lamp parts antique brass lamp parts specialty fasteners specialty hardware cabinet lighting and much much more. If the material is a good conductor like metal touching it to ground for even a brief moment will discharge it.

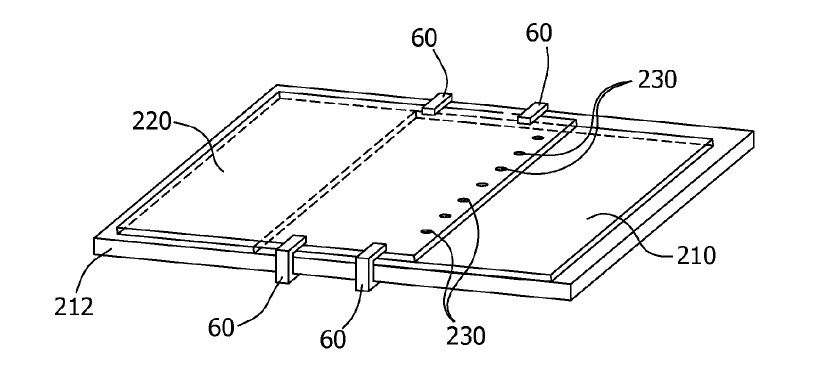

Attach unit base with lamp assembly in place using 4 self tapping sheet metal screws and the pre drilled holes. How to remove corroded metal screws. Saturate a cleaning rag with vinegar and wipe down the metal. Two lamp holes are required for model uv 2023.

Can break with your hands. Creative hobbies elypack 28 piece lamp repair hardware assortment pack includes pipe nipples washers lock nuts 4 7 out of 5 stars 134 7 48 7. The baking soda will abrade the rust without harming the lamp s finish. Attach the unit housing and secure it with two nuts that are placed over the studs mounted on the base.

Use a 1 4 6mm drill bit for drilling the viewport hole.